5 Questions Packaging Engineers Should Ask When Evaluating Sustainable Resins

Switching to sustainable resins doesn’t have to be complicated. Packaging engineers face unique challenges when evaluating new materials, from maintaining performance to meeting corporate sustainability goals. Asking the right questions upfront can save time, reduce costs, and ensure the material is the right fit for your applications.

Here are five essential questions to consider, and why PolyEarthylene® by Verde Bioresins is a standout solution for sustainable packaging.

1. Does the Bioresins work on my existing equipment?

One of the biggest concerns when switching to a sustainable material is process compatibility. Resins that require completely new machinery or line adjustments can create significant cost and operational hurdles.

PolyEarthylene® is designed to run on existing extrusion, molding, and film lines that process polyethylene or polypropylene. This means you can incorporate a sustainable alternative without costly equipment modifications or line downtime.

2. Does it meet performance requirements?

Companies require resins that deliver consistent mechanical strength, durability, and reliable physical properties such as surface finish, flexibility, and barrier performance; without compromising on environmental impact.

PolyEarthylene® offers comparable mechanical performance to polyolefins, including tensile strength and impact resistance, along with consistent physical properties that make it an ideal sustainable alternative to traditional plastics. With PolyEarthylene®, you can maintain the functionality and reliability your products demand while incorporating sustainable materials.

3. Is it truly sustainable?

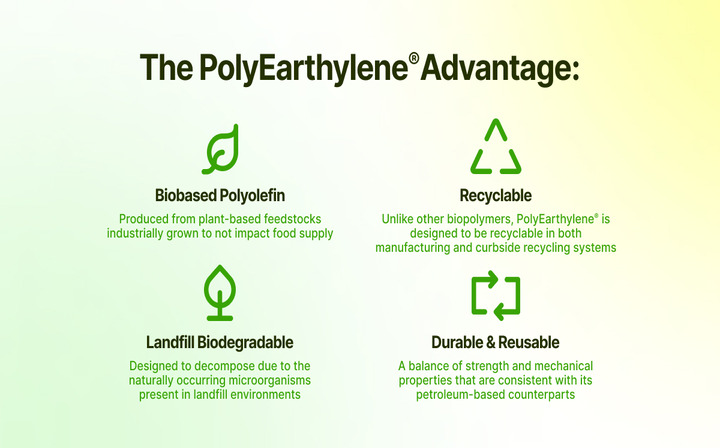

Sustainability claims can be confusing. It’s important to understand whether a resin is biobased, post-consumer recycled material, biodegradable, or compostable, and under what conditions.

At Verde Bioresins, our team of engineers and polymer chemists works closely with your company to identify your sustainability objectives and recommend the PolyEarthylene® grade that best fits your application and environmental goals. With our guidance, you can implement biobased, recyclable, and landfill biodegradable resins that support your sustainability initiatives while maintaining the performance your products require.

4. Will the material help meet regulatory or corporate ESG goals?

Packaging decisions often impact corporate sustainability targets and compliance with evolving regulations. Engineers should consider whether a material contributes meaningfully to these objectives.

PolyEarthylene® supports environment, social, and governance (ESG) initiatives, extended producer responsibility (EPR) programs, and consumer-facing sustainability messaging, helping brands demonstrate measurable progress toward environmental commitments.

5. Is the resin scalable and cost-effective for production?

Adopting a sustainable resin often comes with considerations around cost and production efficiency. Biobased resins can be more expensive than traditional polyolefins due to factors like raw material sourcing, historically higher scrap rates, and traditionally slower cycle times.

PolyEarthylene® addresses these challenges. Most grades can be reground and reincorporated into production at similar ratios and processes as conventional polyolefins, helping to reduce scrap and improve yield. Additionally, cycle times for PolyEarthylene® are comparable to standard polyolefins, making it easier to integrate into existing manufacturing lines.

Produced at commercial scale and priced competitively, PolyEarthylene® allows engineers and packaging teams to balance sustainability with performance and budget objectives, enabling practical adoption without major trade-offs.

Conclusion

When evaluating sustainable resins, asking these five questions ensures your packaging solutions meet both performance and environmental objectives.

Verde’s PolyEarthylene® offers:

-High-performance mechanical and physical properties

-Compatibility with existing extrusion, film and molding equipment

-Biobased, recyclable and landfill biodegradable resin portfolio

-Support for ESG and sustainability goals

-Scalable production at competitive cost

Ready to explore PolyEarthylene® for your packaging? DOWNLOAD PRODUCT BROCHURE HERE

Talk to a specialist

Eager to discuss how our bioresins can benefit your application? Call us now:

Contact Us - Detail Page Form

"*" indicates required fields