Verde Bioresins to Exhibit at PACK EXPO Las Vegas 2025 – Visit Booth SU-38010

Come visit us at Booth SU-38010 in the South Upper Hall Sustainability Pavilion

This year, we are proud to showcase our latest advancements in PolyEarthylene®, a biobased, recyclable and landfill biodegradable alternative to traditional petroleum-plastics. Our team will be available to discuss how Verde’s materials help manufacturers and brand owners meet performance needs while supporting sustainability goals.

At Booth SU-38010, visitors can:

- Explore our full line of PolyEarthylene® resin grades, developed for use in injection molding, extrusion, thermoforming, blow molding, blown film, and other speciality film applications.

- Get expert insights from our technical team about biobased content, recyclability, biodegradability, FDA Title 21 compliance, CA Prop 65 approval and other regulatory standards.

- Discuss partnership opportunities and learn how Verde can support your sustainability needs through collaboration, custom solutions, and supply partnership.

The PolyEarthylene® advantage

PolyEarthylene® is a biobased, recyclable, and landfill biodegradable alternative to traditional petroleum-based polyolefins that can be processed using conventional equipment.

Biobased Polyolefin

Offers a balance of strength and mechanical properties that are consistent with its petroleum-based counterparts.

Renewable & Sustainable

Produced from plant-based feedstocks industrially grown to not impact food supply.

Recyclable

Unlike other biopolymers, PolyEarthylene® is designed to be recyclable in both manufacturing and curbside recycling systems.

Landfill Biodegradable

Designed to decompose due to the naturally occurring microorganisms present in landfill environments.

Talk to a specialist

Eager to discuss how our bioresins can benefit your application? Call us now:

Contact Us - Detail Page Form

"*" indicates required fields

Suitable for durable and single-use applications

The renewable replacement for most petroleum-based polyolefins, PolyEarthylene® is suitable for single-use and durable goods applications because it is thermally stable and durable.

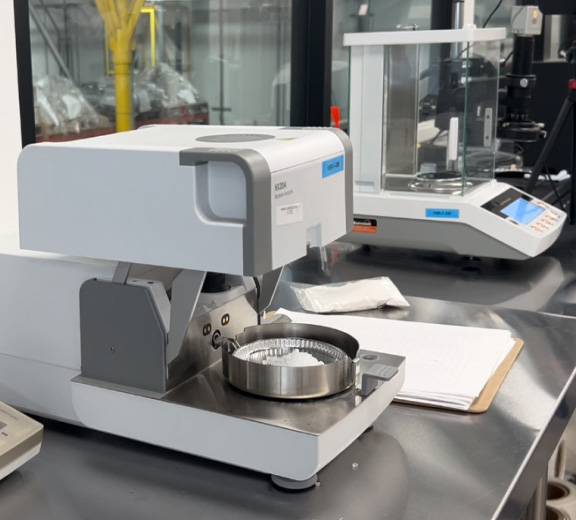

Designed for existing machinery

PolyEarthylene® resins are designed to be processed on existing plastic processing equipment. Companies can switch to PolyEarthylene® without having to invest in new machinery. PolyEarthylene® typically processes at similar conditions, temperatures, and rates as typical polyolefins.

PolyEarthylene® is a cost-effective solution for companies that are looking to switch to more sustainable materials.

Certifications

Verde® Bioresins holds several certifications for its biobased product line, PolyEarthylene®.